In the complex world of cable maintenance, in which precision and endurance is paramount, the use of advanced tools such as wire rope lubricators, wire cleaners have become essential. These new devices are essential to ensure that cables function smoothly and last for longer in an array of industries. Rope lubricators and wire cleaners are crucial for maintenance of cables. In this article, we examine their roles, benefits and the transformative impact on overall efficiency. For more information, click Wire Cleaning

Understanding wire rope lubricators

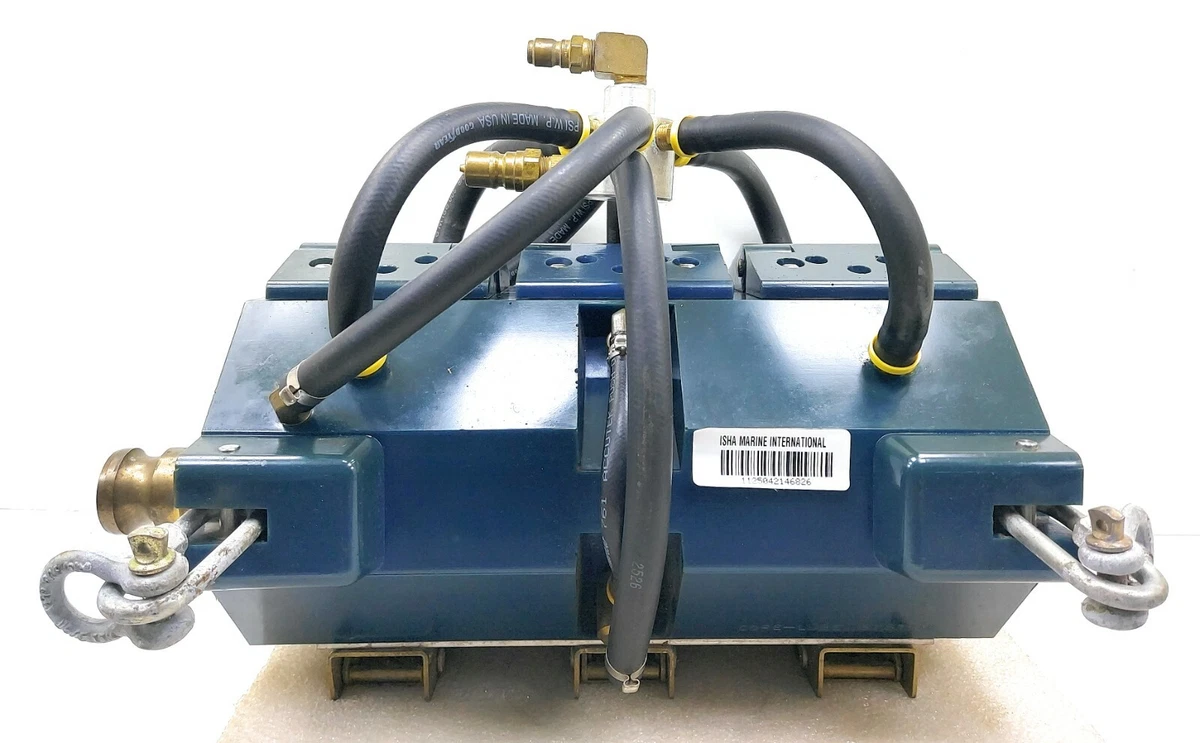

Wire rope lubricators, also called wire rope lubricators, are special equipment that applies grease to the ropes in a methodical manner. This is an essential step for preventing corrosion and friction while increasing the durability of the cable. The lubricator distributes lubricant evenly throughout the length and widening of the rope wire to protect it from wear.

How do you keep cables in good condition with wire cleaners

Wire cleaners, often referred to as cable cleaners, are instrumental in keeping the hygienic condition of cables. They are made to clean out fluids, contaminates and dirt that accumulate on cables during different processes. Wire cleaners are essential in harsh environments, where cables may be subjected to extreme conditions. They are designed to ensure maximum performance and prevent potential damage to the cable.

Optimizing Cable Lifespan:

Wire lubricators and wire cleaners used together can significantly extend the life of cables. With the use of wire rope cleaners to get rid of contaminants and applying the lubrication process, cables are shielded from harmful effects such as friction, corrosion, or external elements. This safeguarding of the cable’s integrity translates into a longer operational lifespan and lower maintenance costs in the long run.

Effectiveness in Application:

Wire Rope Lubricators were designed to be easy to use and efficient in their application. The lubricators are able to be used with a wide range of types and sizes of wire ropes. This allows for flexibility in the maintenance of cables. Systematic and automated lubrication eliminates the risk of a poor application that manual methods could cause.

Adaptability in Challenging Environmentals:

Lubricators for wire ropes, and cleaners for wires, are crucial in industries where cables must endure harsh conditions, such as the ones used in drilling, construction or maritime operations. They are designed to withstand harsh conditions that makes them reliable instruments for cable maintenance in diverse settings.

Cost-effective maintenance solutions:

A proactive approach to maintenance of your cables that includes the use of wire rope cleaners and lubricators is a much more affordable alternative in the long run. The initial investment in these tools is minimal against the potential expenses associated with replacing cables, downtime, and extensive repairs due to ignoring the proper maintenance procedures.

Conclusion:

Wire rope lubricators along with wire cleaners, protect of the integrity of cables. They guarantee high-quality, long-lasting and efficient performance in all industries. Cleaning up pollutants and the application of lubricant contributes to the durability and maintenance of cables. This makes maintenance easier and enhances the efficiency of operations. In a business that relies on cables for critical operations, adopting advanced tools for maintaining cables such as wire rope lubricators and wire cleaners is not only a smart choice, but an absolute necessity.